![]()

Callback Request

Fuel Polishing

When you rely on uninterrupted back up power in case of a mains power failure, it is essential the stored fuel to power your generator remains clean to prevent complete power failure.

The results of complete power failure depending on the industry, could for example, be a cost of millions of pounds in a data centre, a loss of all chilled food stored in a supermarket, or devastatingly a cost of lives in a hospital.

Fuel in back up power supplies could be stored for years without being used. In that time fuel can become contaminated with the likes of water and bacteria. This blocks the back up generator, stopping it from working and causing damage to the system. When a power cut does happen, the back up system fails to work leaving a complete loss of power and devastating consequences.

We have now worked with Craigs and their WASP systems for a number of years and have found that the Fuel Polishing systems do exactly what is required. The 2 micron absolute cleaning and the flexibility to build what we want when we want it. They are ideal for our application with standby power generation.

The Process

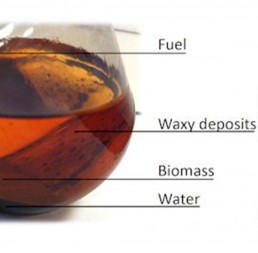

Fuel polishing is the technological cleaning process, which removes water and particulates from diesel fuel, which is stored for the medium to long term. This process keeps the fuel at optimum condition and helps prevent fuel related engine and generator failures.

There are many different stages in the fuel polishing process which follow one after the other in a specific sequence. This ensures the water, sludge, sediment and other contaminate is removed from the fuel.

By removing the bacterial content and neutralising any residual micro-fine particles, the infection simply cannot return; thus ensuring that the WASP Pure Fuel Systems are not only the most effective way of maintaining fuel quality, but is environmentally friendly too, as no chemicals or biocides are used in this process.